99 Failures Pavilion by University of Tokyo

Read here about a pavilion built on tensegrity principles by the University of Tokyo.

Overview

The pavilion was conceived in October 2012 at the University of Tokyo Graduate School of Department of Architecture and Architectural Engineering Yusuke Obuchi laboratory and Atsushi Sato laboratory. The Obayashi Corporation, whose fabrication shops are located near the Toyota Motor factory, played a key role in the implementation.

Photos

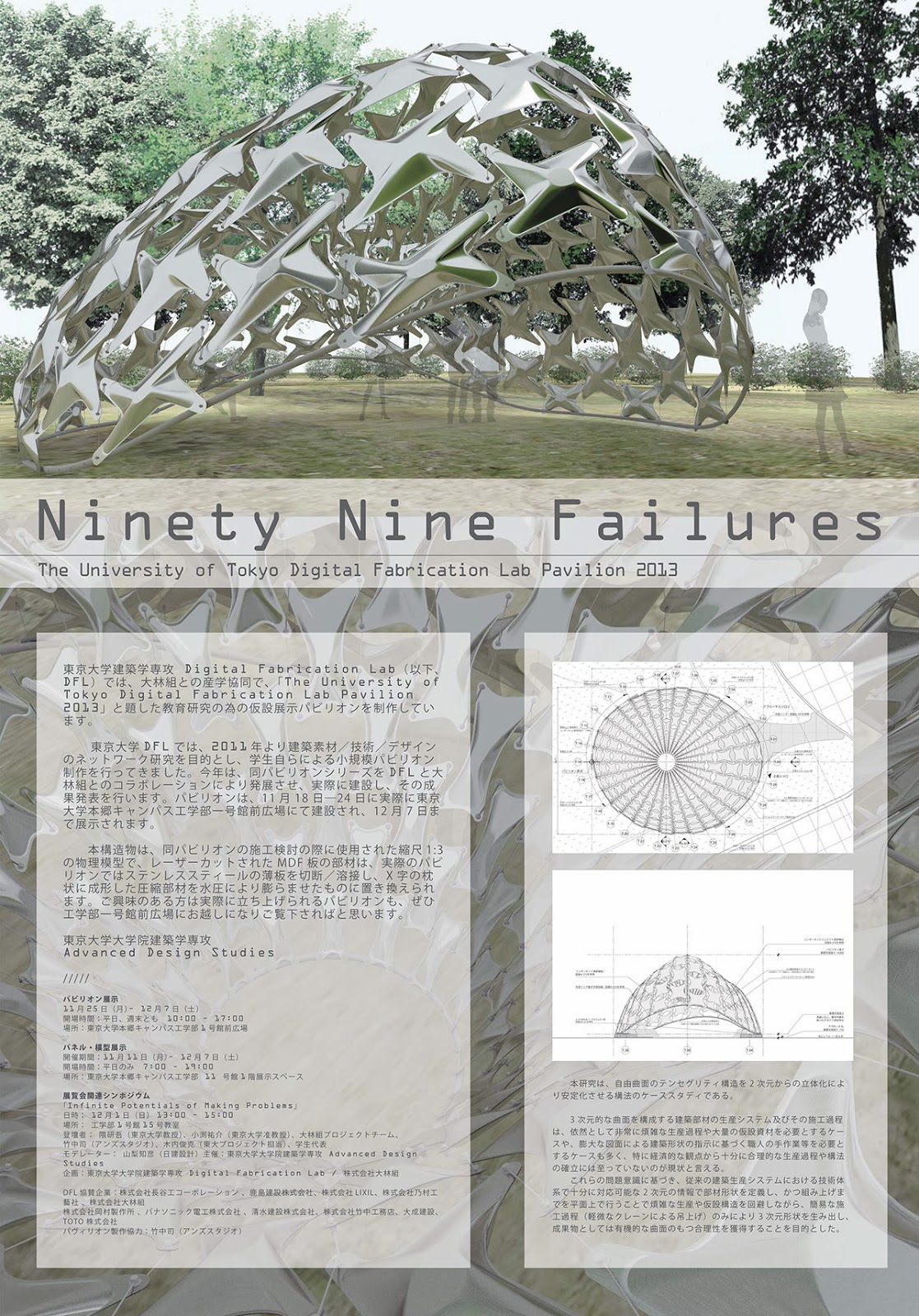

caption="Title Page for Ninety Nine Failures Pavilion, University of Tokyo, December 2013."

link="99 Failures Pavilion Photo Gallery"

caption="Title Page for Ninety Nine Failures Pavilion, University of Tokyo, December 2013."

link="99 Failures Pavilion Photo Gallery"

For an extensive collection of photos, see the 99 Failures Photo Gallery page .

Details

The project was named "Ninety Nine Failures" in a nod to acknowledging the role of failure in urban design. With this name the designers paid homage to the role of failure in exploratory design. In the design process, the designers repeatedly tested different structural models to find a geometry that could smoothly transition from a flat, two-dimensional surface into a sturdy 3D form.

The compression strut is based on a perpendicular "X" form, rounded out into a pillow shape. Each metal component was carefully spaced apart to allow light to pass through and to minimize the impact of wind loads.

Digital mockups were created in Grasshopper and Kangaroo to simulate the tensegrity model and assembly process.

The designers are built a physical 1:3 model from laser cut materials to study the behaviors of the tensegrity test the tension cables. This model tested the accuracy of the structural simulations. The process of assembly remained the same as our last model, with multiple marionette ropes to hoist the entire structure in one go. The structural simulations turned out to be a lot more complicated than expected, and the structural engineers from Obayashi Co. were critical to the success of the project. In addition to material research in computational fabrications, the team experimented and fine-tuned the assembly system. Instead of putting the components on site piece by piece, all of them are linked together to create a 2D surface first and then lifted with a series of cables to form a 3D shell structure. The assembly process is analogous to the way marionette puppets are manipulated by a handheld frame, suspending the puppet by threads.

Prestressed cables pull together layers of thin stainless steel sheets welded together and inflated with hydraulic pressure to create the shape of inflated metal pillows. The task of attaching the cables proved particularly challenging due to the bulk of the assembly and stiffness of the components and cables.

After the materials were assembled on site, a crane pulled the structure upright into its final form.

The pavilion stood outside the University of Tokyo Digital Fabrication Lab at the end of 2013.

Japanese Text

DFLパビリオンの完成及び製作時の写真をアップロードしました。是非ご覧ください。 また、http://www.obuchilab.com/dfl/?p=766より制作過程を記録したムービーもご覧いただけます。

本 研究は、自由曲面のテンセグリティ構造を2次元からの立体化により安定化させる構法のケーススタディとして、2012年10月から2013年12月までに 東京大学大学院建築学専攻小渕祐介研究室(以下、小渕研)、同佐藤淳研究室(以下、佐藤研)と株式会社大林組(以下、大林)との協働にて仮設パビリオンの 設計、プロトタイプ製作を行い、その成果をまとめたものである。部材加工・制作にはAnS Studio・竹中司氏の協力を得た。

本研究のケース スタディにおいては、パビリオンの設計及び施工検討にあたって導入された諸情報技術によりもたらされる1.設計プロセス 2.施工方法 3.建築構造のそ れぞれにおける革新性という観点から、本研究の成果と付随する問題点を検証し、その発展可能性を考察した。

背景および目的

20世紀初頭以来、現在に至るまで国際的な枠組みの中で確立されてきた近現代の建築生産システムは、2次元の図面の組み合わせによる指示を基本とする、直行系の座標を持ったモジュールに従い確立されてきた。

一 方で、フライ・オットーが1982年の自著の中で「今日の目標は自然な建物と都市をつくることである―中略―人間とその技術が自然と不可分であるような状 態を作り上げることである」と述べていることに顕著だが、自然の持つ合理性を取り込むことを目的とした3次元的な曲線・曲面を基調とした有機的な建築への 取り組みは、1960年代以降徐々にその例を増やし、現代では90年代後半以降の情報技術の飛躍的革新の支えを得て、一定量の事例を蓄積するに至ってい る。

しかしながら、3次元的な曲面を構成する建築部材の生産システム及びその施工過程は、依然として非常に煩雑な生産過程や大量の 仮設資材を必要とするケースや、膨大な図面による建築形状の指示に基づく職人の手作業等を必要とするケースも多く、特に経済的な観点から十分に合理的な生 産過程や構法の確立には至っていないのが現状と言える。

本研究では、これらの問題意識に基づき、従来の建築生産システムにおける技 術体系で十分に対応可能な2次元の情報で部材形状を定義し、かつ組み上げまでを平面上で行うことで煩雑な生産や仮設構造を回避しながら、簡易な施工過程の みにより3次元形状を生み出し、成果物としては有機的な曲面のもつ合理性を獲得することを目的とした。

Credits

Original Concept: Ana Luisa Soares

Pavilion Design Team: Ana Luisa Soares, Miguel Puig, Ye Zhang

University of Tokyo teaching staff: Yusuke Obuchi, Toshikatsu Kiuchi, So Sugita, Hironori Yoshida

University of Tokyo students: Christopher Sjoberg, Yeonsang Shin, Miguel Puig, Zhang Ye, Ana Luisa Soares, Ma Sushuang, Tong Shan, Andrea Trajkovska, Quangtuan Ta, Wei Wang, Anders Rod, Benjamin Berwick, Qiaomu Jin, Fawad Osman, Yanli Xiong, Andrea Bagniewski, Kevin Clement, Ornchuma Saraya, Minjie Xu

Project Development Team (The University Of Tokyo): Yusuke Obuchi, Toshikatsu Kiuchi, So Sugita, Ana Luisa Soares, Miguel Puig, Zhang Ye, Christopher Sjorberg, Yeonsang Shin, Ma Sushuang, Tong Shan, Andrea Trajkovska, Quangtuan Ta, Wei Wang, Anders Rod, Benjamin Berwick, Qiaomu Jin, Fawad Osman, Yanli Xiong, Andrea Bagniewski, Kevin Clement, Ornchuma Saraya, Minjie Xu (Obayashi Corporation), Tomoo Yamamoto, Kenichi Misu, Gendai Ono, Yasuo Ichii, Keisuke Fujiwara, Shunsuke Niwa, Tatsuji Kimura, Masaru Emura, Taiki Byakuno, Takahide Okamoto

Structural Engineer: Jun Sato

Fabrication Of Components: Tsukasa Takenaka (Ans Studio)

Construction: Multibuilder

Fabrication: Togari Kogyo

Sponsors: Haseko Corporation, Kajima Corporation, Lixil Corporation, Nomura, Obayashi Corporation, Okamura, Panasonic, Shimizu Corporation, Takenaka Corporation, Taisei Corporation, Toto

Obayashi Corporation staff: Tomoo Yamamoto, Kenichi Misu, Gendai Ono, Yasuo Ichii, Keisuke Fujiwara, Shunsuke Niwa, Tatsuji Kimura, Masaru Emura, Taiki Byakuno, Takahide Okamoto

Structural engineer: Jun Sato

Fabrication of components: Tsukasa Takenaka (AnS Studio)

Construction: Multibuilder

Materials

Compressive components: stainless steel plates with 0.5 mm / 0.8 mm / 1.2 mm / 1.5 mm thickness Tension cables: stainless steel cables in 3 mm diameter Base ring: stainless steel pipe in 48mm diameter Foundation: precast concrete blocks Furniture: painted plywood Weight: 1.5 t (upper structure in stainless steel), 1 t (concrete foundation) Design Phase: October 2012 – March 2013 Design development, fabrication & construction: April – November 2013 Completion date: 24 November 2013

Links, References

Video: https://vimeo.com/80980278

Obuchilab pages: http://www.obuchilab.com/dfl/?p=766 http://obuchi-lab.blogspot.com/2013/09/pavilion-meeting-with-obayashi-co.html http://obuchi-lab.blogspot.com/2013/11/component-assembly.html http://obuchi-lab.blogspot.com/2013/08/g30-summer-pavilion-work-in-progress-04.html

Domus article summary: http://www.domusweb.it/en/architecture/2014/01/07/99_failures_and_onepavilion.html

Designer's website: http://www.falaatelier.com/g30