Tendon, Materials: Difference between revisions

m (→Nylon: syntax fix) |

m (→Rubber Bands: syntax fixes) |

||

| Line 48: | Line 48: | ||

===Rubber Bands=== | ===Rubber Bands=== | ||

A rubber band (in some regions known as a binder, elastic band, lackey band, laggy band, lacka band or gumband) is a short length of | A rubber band (in some regions known as a binder, elastic band, lackey band, laggy band, lacka band or gumband) is a short length of [http://en.wikipedia.org/wiki/Rubber| rubber] and [http://en.wikipedia.org/wiki/Latex| latex] formed in the shape of a loop. While other rubber products may use [http://en.wikipedia.org/wiki/Synthetic_rubber| synthetic rubber], rubber bands are primarily manufactured using [http://en.wikipedia.org/wiki/Natural_rubber| natural rubber] because of its superior elasticity. | ||

====Thermodynamics of Rubber Bands==== | ====Thermodynamics of Rubber Bands==== | ||

Temperature affects the elasticity of a rubber band in an unusual way. Heating causes the rubber band to contract, and cooling causes expansion.[http://en.wikipedia.org/wiki/Rubber_band#cite_note-8|[9 | Temperature affects the elasticity of a rubber band in an unusual way. Heating causes the rubber band to contract, and cooling causes expansion.[http://en.wikipedia.org/wiki/ Rubber_band#cite_note-8|[9]] | ||

An interesting effect of rubber bands in [[http://en.wikipedia.org/wiki/Thermodynamic|thermodynamics | An interesting effect of rubber bands in [[http://en.wikipedia.org/wiki/Thermodynamic| thermodynamics] is that stretching a rubber band will produce heat (press it against your lips), while stretching it and then releasing it will produce an [http://en.wikipedia.org/wiki/Endothermic| endothermic] reaction, causing it to become cooler. This phenomenon can be explained with [http://en.wikipedia.org/wiki/Gibb%27s_Free_Energy| Gibb's Free Energy]. Rearranging ΔG=ΔH-TΔS, where G is the free energy, H is the [http://en.wikipedia.org/wiki/Enthalpy| enthalpy], and S is the [http://en.wikipedia.org/wiki/Entropy| entropy], we get TΔS=ΔH-ΔG. Since stretching is nonspontaneous, as it requires an external heat, TΔS must be negative. Since T is always positive (it can never reach [http://en.wikipedia.org/wiki/Absolute_zero| absolute zero]), the ΔS must be negative, inferring that the rubber in its natural state is more entangled (fewer [http://en.wikipedia.org/wiki/Microstate_%28statistical_mechanics%29| microstates]) than when it is under tension. Thus, when the tension is removed, the reaction is spontaneous, leading ΔG to be negative. Consequently, the cooling effect must result in a positive [http://en.wikipedia.org/wiki/Gibb%27s_Free_Energy| ΔG], so ΔS will be positive there. | ||

====Rubber band sizes==== | ====Rubber band sizes==== | ||

A rubber band is given a [quasi-]standard number based on its dimensions. Generally, rubber bands are numbered from smallest to largest, width first. Thus, rubber bands numbered 8-19 are all 1/16 | A rubber band is given a [quasi-]standard number based on its dimensions. Generally, rubber bands are numbered from smallest to largest, width first. Thus, rubber bands numbered 8-19 are all 1/16 [http://en.wikipedia.org/wiki/Inch| inch] wide, with length going from 7/8 inch to 3 1/2 inches. Rubber band numbers 30-34 are for width of 1/8 inch, going again from shorter to longer. For even longer bands, the numbering starts over for numbers above 100, again starting at width 1/16 inch. | ||

The origin of these size numbers is not clear and there appears to be some conflict in the "standard" numbers. For example, one distributor has a size 117 being 1/16 inch wide and a size 127 being 1/8 inch wide. However, an OfficeMax size 117 is 1/8 inch wide. | The origin of these size numbers is not clear and there appears to be some conflict in the "standard" numbers. For example, one distributor has a size 117 being 1/16 inch wide and a size 127 being 1/8 inch wide. However, an OfficeMax size 117 is 1/8 inch wide. | ||

Revision as of 07:58, 13 January 2019

Tendon, Materials

Read here about physical materials that are suitable for tension members of models and tensegrity structures. For general tendon concepts and issues, see tendon.

Comparing Tendon Materials

All tendons stretch under load in a tensegrity structure, but some materials stretch more than others. See below for a chart of approximate stretch in rope under 30 percent of its breaking load.

Stretch patterns in tensegrity tendons vary by material. For example:

- Nylon stretches far more than Dacron.

- Polypropylene has little elasticity but has only about 60 percent the strength of Dacron.

- Kevlar and Spectra stretch about 1 to 2 percent or less. Kevlar is several times stronger than steel, but it’s not durable when bent sharply, so it is not suitable for tensegrities where the tendons bend around a strut-end. Spectra is even stronger than Kevlar and accepts bending. It’s also good at resisting chafe. however, it tends to “creep” slightly under a heavy sustained load such as it bears in any pre-stressed tensegrity.

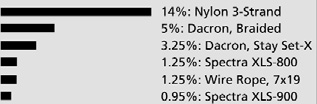

Inventory of Tendon Materials

A review of materials used for tendons.

Synthetic Polymers

Dacron

Dacron, a polyester fiber, stretches only about 3.5 to 5 percent under the same conditions, so it is preferred to nylon. Fuller preferred Dacron for his models. Dacron is known outside North America as Terylene, Duron, Fortrel, A.C.E., and Kodel.

Nylon

Nylon is a generic designation for a family of synthetic polymers known generically as polyamides, first produced by Dupont in 1935. Nylon is one of the most commonly used polymers.

Nylon stretches about 10 to 15 percent under a load equal to 30 percent its breaking strength; therefore, it is used in light models only.

Snelson used nylon in his original X-shaped tensegrity sculpture, Early X-Piece (1948). "For George" (1970) was composed of black bamboo and nylon.

Bruce Hamilton's kits are made of 70lb Jinkai nylon monofilament line that is attached to nylon washers, with the fasteners being 8 - 32 threaded nylon machine screws. See his website for details.

Spectra

Spectra is ultra-high molecular weight polyethylene (UHMWPE) fibers yield very high strength and cut resistant ropes that can stand-in for steel cables at one tenth their weight. WV prefers it for his hammock stands.

Spectra, like Kevlar, stretches about 1 to 2 percent or less. Spectra is even stronger than Kevlar and accepts bending. It’s also good at resisting chafe. however, it tends to “creep” slightly under a heavy sustained load such as it bears in any pre-stressed tensegrity.

Kevlar

Kevlar stretches about 1 to 2 percent or less. Kevlar is several times stronger than steel, but it’s not durable when bent sharply, so it is not suitable for tensegrities where the tendons bend around a strut-end. Compare with Spectra, above.

Rubber

Natural rubber is made from latex which is acquired by tapping into the bark layers of the rubber tree. Once the latex has been “tapped” and is exposed to the air it begins to harden and become elastic, or “rubbery.” Synthetic rubber is made by mixing petroleum byproducts in a reactor with soapsuds which produces milky liquid latex. The liquid is then coagulated into rubber chunk and then sold to rubber manufacturers who in turn melt the rubber down and pour it into molds to create various products. See rubber band, below.

Rubber Bands

A rubber band (in some regions known as a binder, elastic band, lackey band, laggy band, lacka band or gumband) is a short length of rubber and latex formed in the shape of a loop. While other rubber products may use synthetic rubber, rubber bands are primarily manufactured using natural rubber because of its superior elasticity.

Thermodynamics of Rubber Bands

Temperature affects the elasticity of a rubber band in an unusual way. Heating causes the rubber band to contract, and cooling causes expansion.Rubber_band#cite_note-8|[9] An interesting effect of rubber bands in [thermodynamics is that stretching a rubber band will produce heat (press it against your lips), while stretching it and then releasing it will produce an endothermic reaction, causing it to become cooler. This phenomenon can be explained with Gibb's Free Energy. Rearranging ΔG=ΔH-TΔS, where G is the free energy, H is the enthalpy, and S is the entropy, we get TΔS=ΔH-ΔG. Since stretching is nonspontaneous, as it requires an external heat, TΔS must be negative. Since T is always positive (it can never reach absolute zero), the ΔS must be negative, inferring that the rubber in its natural state is more entangled (fewer microstates) than when it is under tension. Thus, when the tension is removed, the reaction is spontaneous, leading ΔG to be negative. Consequently, the cooling effect must result in a positive ΔG, so ΔS will be positive there.

Rubber band sizes

A rubber band is given a [quasi-]standard number based on its dimensions. Generally, rubber bands are numbered from smallest to largest, width first. Thus, rubber bands numbered 8-19 are all 1/16 inch wide, with length going from 7/8 inch to 3 1/2 inches. Rubber band numbers 30-34 are for width of 1/8 inch, going again from shorter to longer. For even longer bands, the numbering starts over for numbers above 100, again starting at width 1/16 inch. The origin of these size numbers is not clear and there appears to be some conflict in the "standard" numbers. For example, one distributor has a size 117 being 1/16 inch wide and a size 127 being 1/8 inch wide. However, an OfficeMax size 117 is 1/8 inch wide.

|| Size || Length (in) || Width (in) || Thickness (in) || || 10 || 1.25 || 1/16 || 1/32 || || 12 || 1.75 || 1/16 || 1/32 || || 14 || 2 || 1/16 || 1/32 || || 31 || 2.5 || 1/8 || 1/32 || || 32 || 3 || 1/8 || 1/32 || || 33 || 3.5 || 1/8 || 1/32 || || 61 || 2 || 1/4 || 1/32 || || 62 || 2.5 || 1/4 || 1/32 || || 63 || 3 || 1/4 || 1/32 || || 64 || 3.5 || 1/4 || 1/32 || || 117 || 7 || 1/16 || 1/32 ||

Connelly notes plastibands last much longer than rubber bands.[Aug 2010]

Link: http://www.the-rubber-band.com/

Polyurethane

Plastibands are made with latex-free polyurethane. Baumgartens.com, the manufacturer, says they are much stronger than ordinary plastic bands and contain no additives or plasticizers. They are marketing them as a "green" product. The bands are available from a variety of art supply stores and amazon.com. They're listed on the staples.com website, but the local store has never stocked them. (Earnhardt, Aug 2010)

Connelly uses plastibands instead of rubber bands for his tensegrity constructions, he says they last much longer than rubber bands.[Aug 2010]

Steel

Steel is usually deployed in the form of wire, though it can be deployed as a chain: see chain.

A wire is a single, usually [[1]], string of metal. Wires are used to bear mechanical [[2]] and to carry [[3]] and [[4]] [[5]]. Wire is commonly formed by [[6]] the metal through a hole in a [[7]] or [plate]. [[8]] [[9]] are determined by various [gauges]. Not all metals and metallic [[10]] possess the physical properties necessary to make useful wire. The metals must in the first place be [[11]] and strong in tension, the quality on which the utility of wire principally depends. The metals suitable for wire, possessing almost equal ductility, are [[12]], [[13]], [[14]], [[15]], aluminium and [[16]]; and it is only from these and certain of their [[17]] with other metals, principally [[18]] and [[19]], that wire is prepared. By careful treatment extremely thin wire can be produced. Special purpose wire is however made from other metals (e.g. [[20]] wire for [bulb] and [tube] filaments, because of its high melting temperature). Copper wires could be plated with other metals, such as tin, nickel, and silver to handle different temperatures.

Wire Roap

See wire roap.

Inox

Inox is stainless steel. Snelson used stainless steel in his sculpture "Forest Devil" (1975), "Rainbow Arch" (2001), "Sun River" (1967) and others. His most common choice for deployments is aluminum struts with stainless steel tendons.

See inox.

Steelon

Steelon is a brand name for plastic or nylon coated wire roap. Snelson used Steelon and aluminum in his sculpture "Spring Street" (1964), "Sun Run" (1967), and others.

Piano Wire

Piano wire is a specialized type of [[21]] made for use in [[22]] and other musical instrument strings, as well as many other purposes. It is made from [[23]] high-carbon[24]], also known as [steel]. General-purpose, high-carbon steel, drawn music wire (such as [[25]] A228) is manufactured in both [[26]] and [[27]] music wire gauges (m.w.g.) in diameters as small as 0.006 inch up to 0.192 inch (0.15 to 4.8 mm). A small number of companies produce the tough, high tensile polished wire intended for limited music instrument markets, which is manufactured from steel of a specific composition by [drawing]. Musical instrument strings, modern electric guitars in particular, are among the most demanding of all its applications. Placed under high tension, they are subject to repeated blows, repeated bending, are stretched and slackened during tuning and, in piano service, are still expected to last for decades. The wire must also be extremely consistent in size: variations greater than 0.0003 inch (8 μm) will produce audible falseness in modern instruments.

Music wire

"Music wire" is the USA name for high strength steel wire, it's also available in stainless steel which might look nicer?

Music wire is sold by weight and packaged in tight coils. It springs back to a gentle curve but can be straightened using a series of opposed rollers. It requires careful handling for safety and appearance, since it can be marred by [[28]], and it requires special cutters, as the hardened steel will otherwise quickly dull the cutter.

It is hard and springy, you will need to think carefully about connections, perhaps neatly twisting the ends like guitar strings. Normal wire cutters (for soft wire) will be nicked by this hard wire, there are special wire cutters with hardened edges just for music wire. Also, be careful to not puncture your fingers or other body parts with the sharp wire ends.

A sample supplier: [[29]]

Amsteel Wire

Amsteel is a registered trademarked brand name for a nonrotational, Samthane-coated 12-strand single braid that yields high strength and low stretch; equivalent to wire rope with one-seventh the weight. The manufacturer claims the product is flexible, spliceable, and resists flex-fatigue and abrasion. It floats-will not absorb water, is easily spliced, extremely lightweight, durable-outlasts wire rope, and is spliceable--Class II 12-strand. Sample Link: [[30]]

Electroluminescent Wire

[31]] wire (often abbreviated to EL wire) is a thin diameter [wire] coated in a [[32]] which glows when an [current] is applied to it. It can be used in a wide variety of applications- vehicle and/or structure decoration, safety and emergency lighting, toys, clothing etc - much as rope light or [lights] are often used. Unlike these types of strand lights, EL wire is not a series of points but produces a 360 degree unbroken line of visible light.

See also lighting.

Polyethelyne

See Spectra, below.

Chain

Snelson used bead chain in his sculpture "Harry's Hen" (1960), "Bead Chain Helix" (1959), and others.

Rope

A rope is a length of [[33]], twisted or [[34]] together to improve strength for pulling and [[35]]. It has [strength] but is too flexible to provide [strength](i.e. it can be used for pulling, but not pushing). Rope is thicker and stronger than similarly constructed cord, line, [[36]], and [[37]].

Spectra Rope

See Spectra, above.

Link: [[38]]

Thread

Snelson used thread and cardboard in his earliest tensegrity sculpture "Bat Wing Piece" (1948).